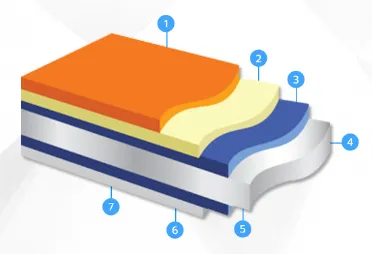

แผ่นฉนวนกันความร้อน EPS (Expanded Polystyrene Foam) ชนิดที่ไม่เกิดการลามไฟเนื่องจากเราใช้โฟมประเภท F-Grade ซึ่งผลิตจากวัสดุโฟมขาวคุณภาพสูง และได้รับมาตรฐาน ISO 9001:2015

คุณสมบัติแผ่นฉนวน BCF Panel (Food Grade EPS Wall)

- แผ่นฉนวนกันความร้อนชนิด EPS หรือชื่อเต็มเรียกว่า Expanded Polystyrene Foam ซึ่งเป็นแผ่นฉนวนที่ไม่ก่อให้เกิดการลามไฟ และมีคุณสมบัติที่ช่วยเก็บความเย็นได้ดี เพื่อการนำไปใช้ประโยชน์ในอุสาหกรรมต่างๆ เช่น โรงงานห้องเย็น, ห้องคลีนรูม, ไลน์ผลิต, โรงงานที่เก็บอาหาร, ห้องฟรีส, ห้องผ่าตัด และอื่นๆ ยังรวมถึงการสร้างบ้านอีกด้วย

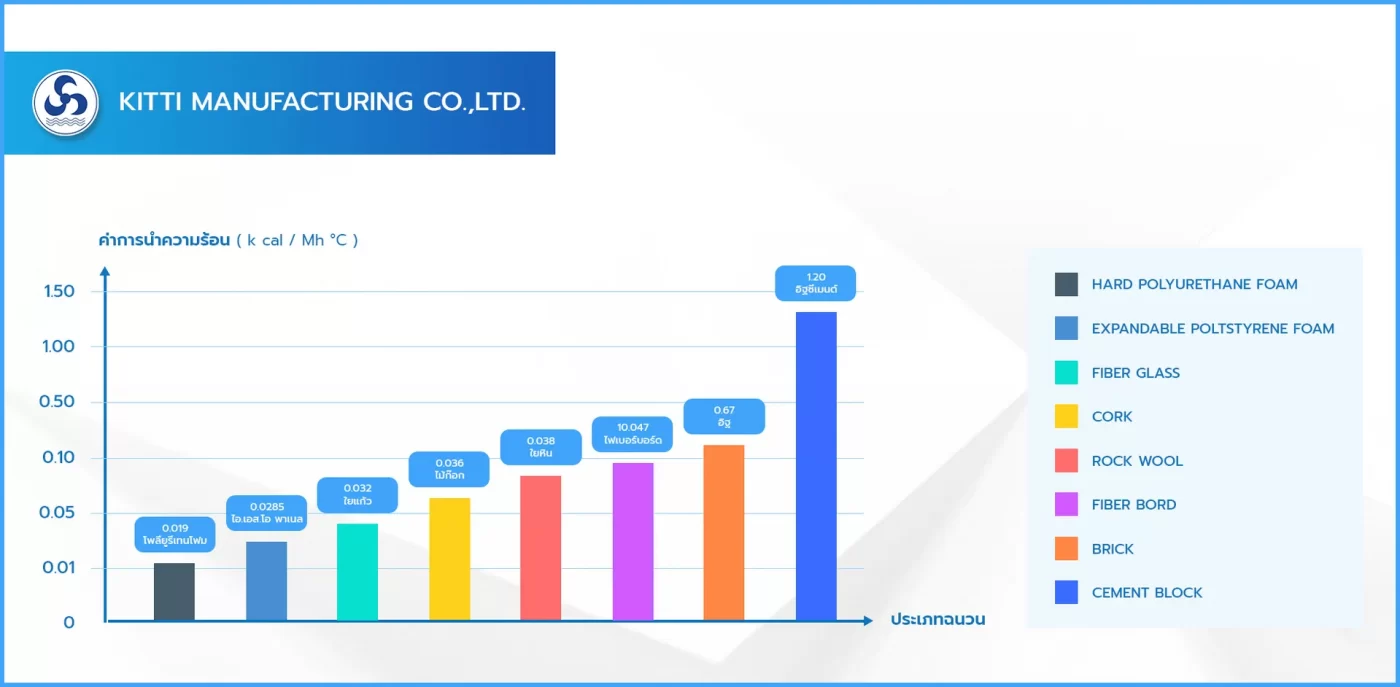

- ค่าการนำความร้อน หรือค่า K value ของแผ่นฉนวนฯ มีค่าอยู่ที่ 0.034 W/m.K

- ช่วงอุณหภูมิที่เหมาะแก่การใช้งาน โดยเฉลี่ยอยู่ที่ -40 °C ไปจนถึง 25 °C (ขึ้นอยู่กับความหนาแน่นของโฟม)

- ความหนาแน่น มีตั้งแต่ 0.8 ibs/ft³, 1.25 lbs/ft³ และ 2 lbs/ft³ ซึ่งมีคุณสมบัติช่วยการรับแรงกด(Compressive strength) ได้ดีอีกด้วย โดยแต่ละขนาดจะมีความเหมาะสมที่แตกต่างกันขึ้นอยู่กับการใช้งาน และปัจจัยอื่นๆ ร่วมด้วย

- โครงสร้างวัสดุแผ่นฉนวนกันความร้อนจะใช้กาวที่เป็นตัวสร้างเซลล์ให้ติดกับผนังทั้งสองด้านและไม่ทำให้น้ำหนักมากเกินไป (ข้อมูลรอเพิ่ม จากการชั่งน้ำหนัก จาก ตรม ตามแต่ละขนาด)

- สามารถลดต้นทุนค่าใช้จ่ายต่างๆ ได้ เช่น ค่าไฟเมื่อใช้งานห้องเย็น หรือห้องอุณหภูมิบวก ช่วยทำให้อุณหภูมินั้นคงที่ได้ไวยิ่งขึ้น ยืดอายุการใช้งานของแผ่นได้เป็นอย่างดี

- ข้อดีของแผ่นฉนวนกันความร้อน EPS ช่วยป้องกันความร้อน และความชื้น อีกทั้งยังสามารถรักษาอุณหภูมิความเย็นได้เป็นอย่างดี เหมาะแก่การจัดเก็บวัตถุดิบอาหารที่ต้องใช้อุณหภูมิติดลบไปจนถึงอุณหภูมิบวก นอกจากนี้ยังช่วยลดต้นทุนในส่วนของค่าไฟฟ้า การใช้งานจึงตอบโจทย์ผู้ประกอบการด้านอาหาร รวมไปถึงอุตสาหกรรมยา และเคมีชนิดต่างๆ ที่จำเป็นต้องเก็บสินค้าไว้ในห้องเย็นเป็นระยะเวลานาน

- เป็นผลิตภันฑ์ปลอดสาร CFCs ซึ่งได้ยอมรับจากทั่วโลก ไม่เป็นอันตรายต่อมนุษย์ และเป็นมิตรต่อสิ่งแวดล้อม

- ได้รับการรับรองจากมาตรฐานระบบ GMP และ HACCP

- ด้านความคุ้มค่าต่อการลงทุน แผ่นฉนวนฯชนิด EPS มีราคาที่ถูกกว่าชนิดอื่นๆ เช่น PU, PIR และ ROCKWOOL ทั้งนี้ขึ้นอยู่กับความจำเป็นในด้านการใช้งานของลูกค้า

- แผ่นฉนวนฯ EPS เหมาะกับการใช้งานในหลากหลายอุตสาหกรรม เช่นห้องเย็น, ห้องปลอดเชื้อ, ห้องไลน์ผลิต และอื่นๆ อีกมากมาย

BCF PANEL พร้อมส่งมอบความคุ้มค่า และช่วยเหลือผู้ประกอบการขับเคลื่อนผลกำไรในระยะยาว รวมถึงเน้นการให้บริการที่ครบถ้วน ตอบโจทย์การใช้งานของลูกค้าเพื่อให้เกิดการลงทุนที่คุ้มค่า งบประมาณไม่บานปลาย

Insulation Panels: Expanded Polystyrene Foam (Eps) BCF Panel

The Expanded Polystyrene Foam (Eps) BCF Panel is designed for cold room walls. Eps Panels are lightweight yet strong insulation panels with a lifespan of 15-20 years when properly maintained. Due to their high insulation value, they are widely used in cold rooms, production lines, clean rooms, and sterile rooms. They also prevent moisture, protecting temperature-sensitive products. You can be confident that using these panels ensures product quality, provided they are used properly.

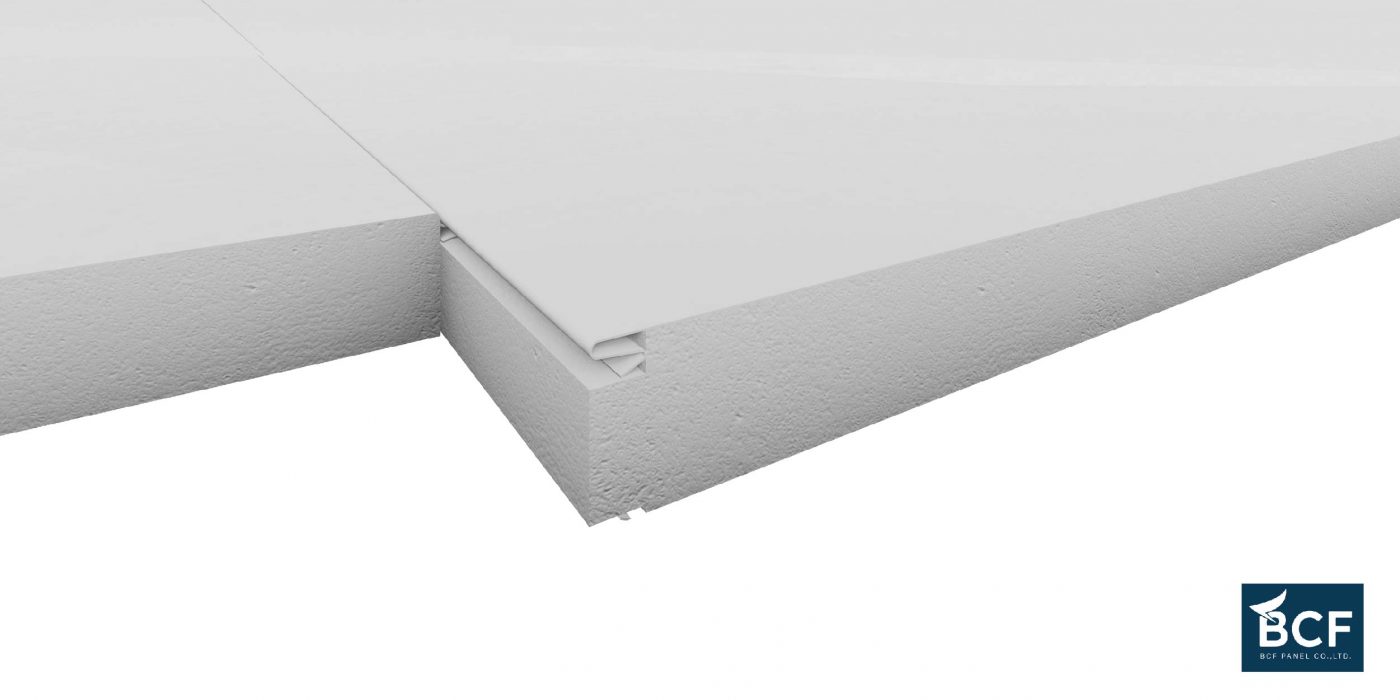

The Expanded Polystyrene Foam (Eps) BCF Panel uses self-extinguishing material or F Grade and features a P-Lock system. This design enhances the product’s strength and provides safety for industries requiring Eps installations, including protection in the event of a fire. The suitability of the panels depends on the specific application.

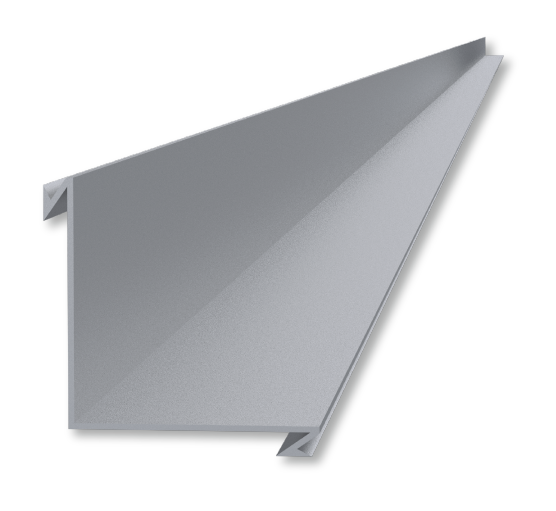

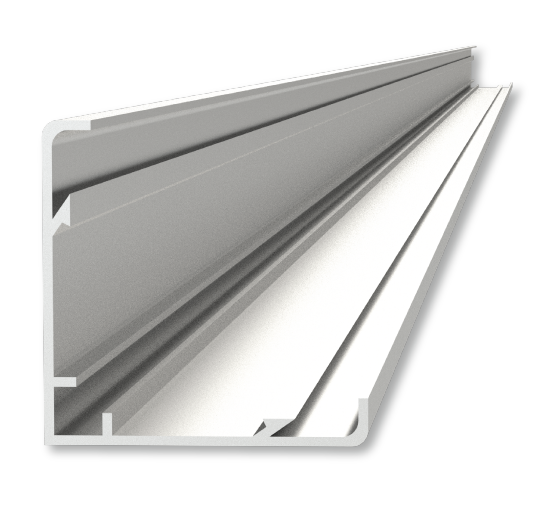

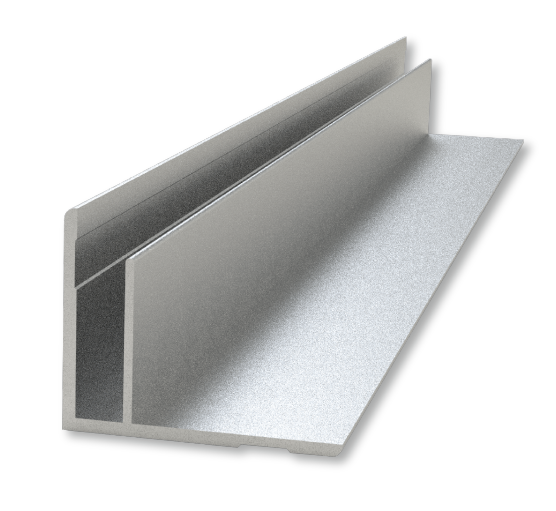

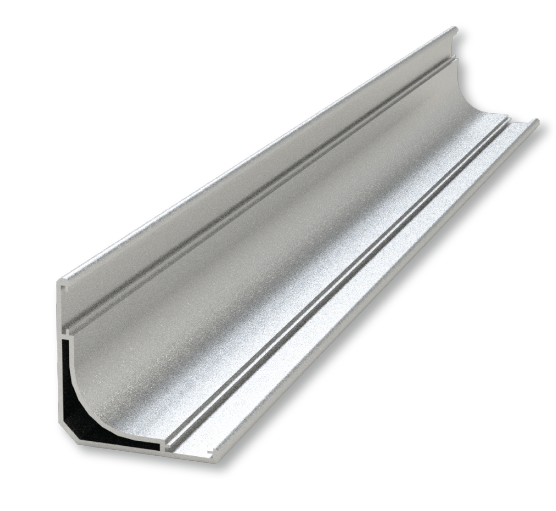

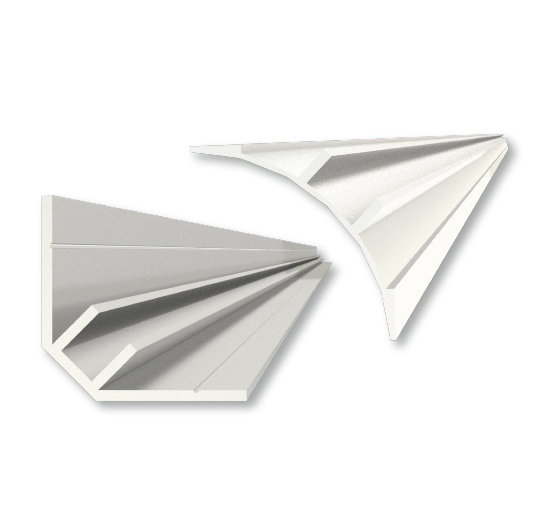

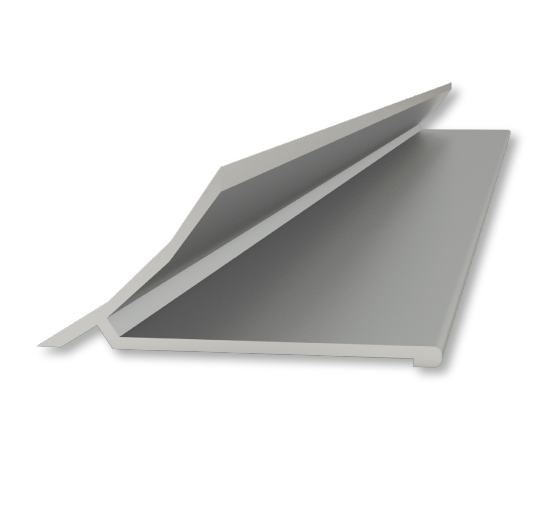

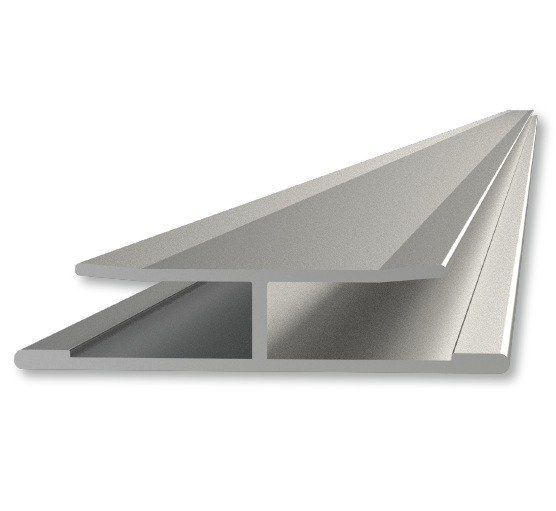

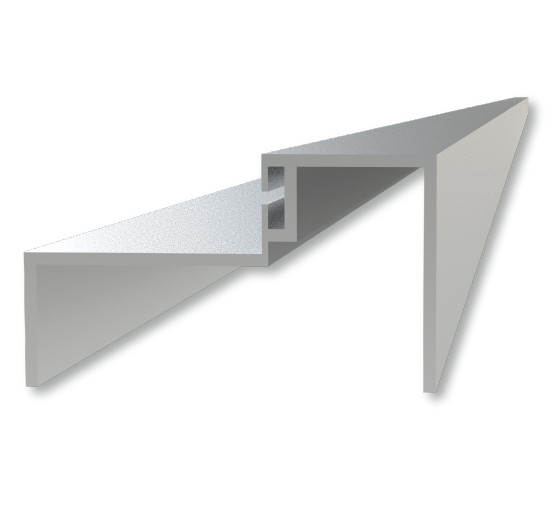

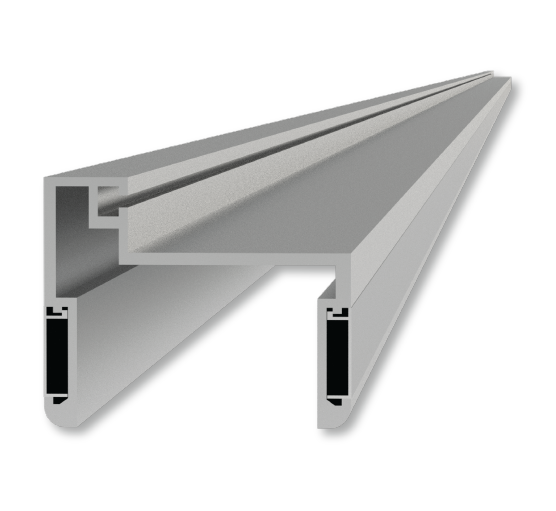

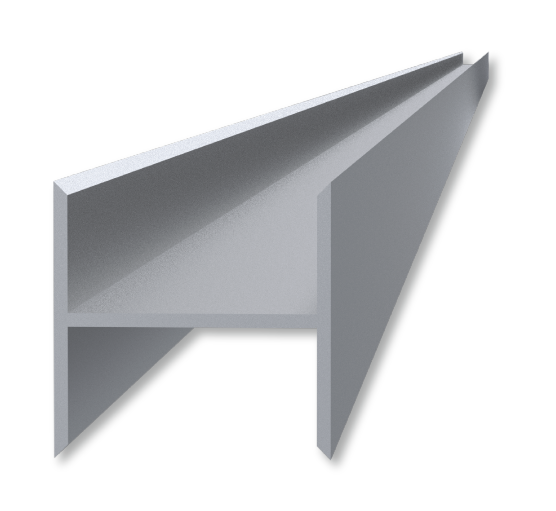

How are the features of the Sandwich Panel with the P-LOCK system from BCF PANEL better than those on the market?

-

-

Proper use of the P-LOCK system, including ironing the sheets to a length of 5 cm and ensuring the locking system is secure at various angles. This enhances efficiency, strength, and extends the lifespan of the wall panel.

-

The P-LOCK system is more robust than the U Lock, S Lock, and Z-Lock systems on the market due to its 5-layer fold. This design creates an optimal gap during formation, making the panel highly resistant to impact and effectively supporting weight, which eliminates the need for a backing plate at the joint. Additionally, it helps prevent leakage, reduces the risk of moisture condensation and water droplet reactions.

-

-

The BCF lock system simplifies installation by ensuring that the joints between the sheets are visually appealing and maintain a neat appearance, making the finishing process easier. Additionally, the special locking system design reduces the risk of damage when removing the panel sheets.

-

-

The panels help reduce costs, such as electricity for cold or positive temperature-controlled rooms, by stabilizing temperatures more quickly. A well-designed lock minimizes gaps between sheets, preventing the exchange of outside and inside temperatures. Additionally, the design extends the lifespan of the sheets.

-

It is suitable for industries including food factories, food storage facilities, freeze room, clean rooms, operating rooms, and many others.

How is BCF Panel different from other vendors?

-

- BCF Panel’s prefabricated insulation panels feature a superior P-Lock (Performance Lock) design compared to the Z-Lock. The P-Lock design includes a joint modification that creates a smaller gap after formation, reducing condensation at the panel seams and improving temperature retention.

- To ensure the highest quality, only new foam pellets are used in production. Recycled foam pellets are not used.

- Passed the German DIN 4102-1 standard test with a Class B2. This indicates that while the material is combustible, it self-extinguishes within 1 second and doesn’t produce droplets, making it safe in the event of a fire. Covered with steel, the insulation helps prevent the spread of fire, allowing for safe evacuation. This differs from concerns raised by some insulation sheet vendors.

- Soundproofing ability passed the ISO 10140-2 standard test, with a result of 22 dB thanks to the closed-cell foams.

- A check and density test are conducted before entering the warehouse to await production.

- The k-Value of 0.032 W/mK can reduce heat more effectively than a wall made of brick and general cement. The lower the k-value, the better. Brick or cement materials have a k-value of 0.66 W/mK, which is higher and results in lower heat protection ability.

- Suitable for maintaining temperatures from -50°C to +70°C

- Available in densities of 1.00, 1.25, 1.50, and 2 lbs, these panels are strong and can handle pressures from various sources, including strong winds, up to 2000 Pascals. At 1% stress, they can support an average weight of 23.34 Kilonewton/Sqm. At 10% stress, they can support an average weight of 139.82 Kilionewton/ Sqm(Compressive strength And Wind Load )

- Reduces water absorption for up to 4 days, with a percentage change in foam mass of 1.43-1.58%, which is considered low compared to other types of insulation materials.

- The P-Lock insulation sheet®, a patented BCF panel, features a lock system with steel components measuring up to 5 cm. Its closed-cell, lightweight material structure provides excellent impact absorption, contributing to a locking system that is more efficient than traditional systems currently available on the market.

- Free from CFCs, making it environmentally friendly and not contributing to the depletion of the ozone layer.

- Certified by GHP and HACCP standards according to international guidelines.

- Heat-resistant and moisture-resistant with weather changes, it maintains temperature effectively, helping to save on electricity costs over time.

Strengths

-

- Offers a more efficient locking system than the traditional models on the market.

- Specifically made for cold rooms, clean rooms, and production environments.

- More cost-effective than PIR PU.

- EPS foam available in densities of 0.8, 1.0, 1.25, 1.5, and 2.0 lbs/ft³.

- Steel thickness options of 0.35 TCT, 0.40 TCT, and 0.45 TCT Bacteria + food Grade.

Weaknesses

-

- Has a k-Value of 0.032 W/mK, which is higher than that of PU PIR.

- For high negative temperature rooms, a thicker sheet is required, which takes up more space compared to PU PIR.

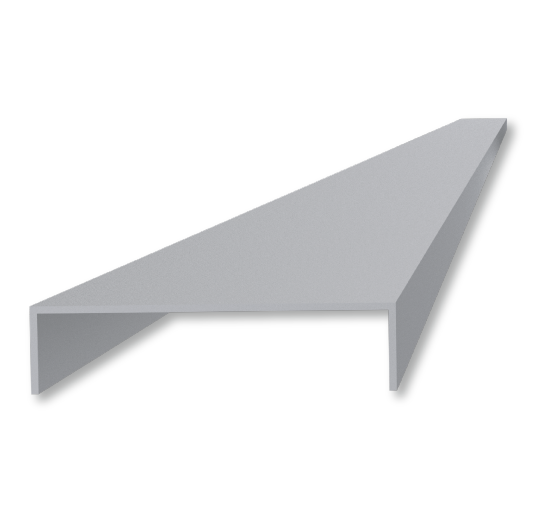

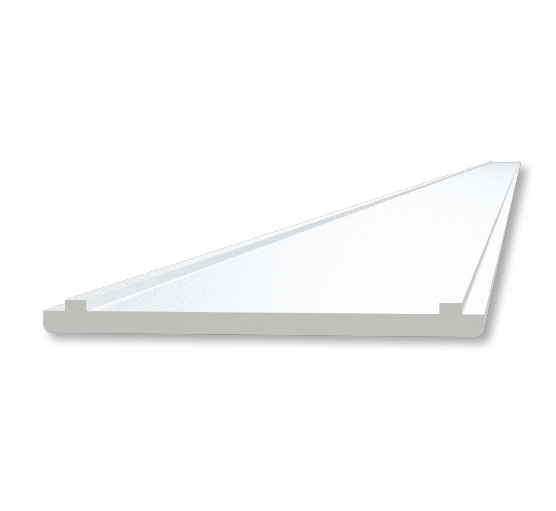

Panel Sheet Size

-

- Width: 1200 mm

- Length: Customizable based on customer requirements

- Thickness: Starting from 40 mm up to 300 mm